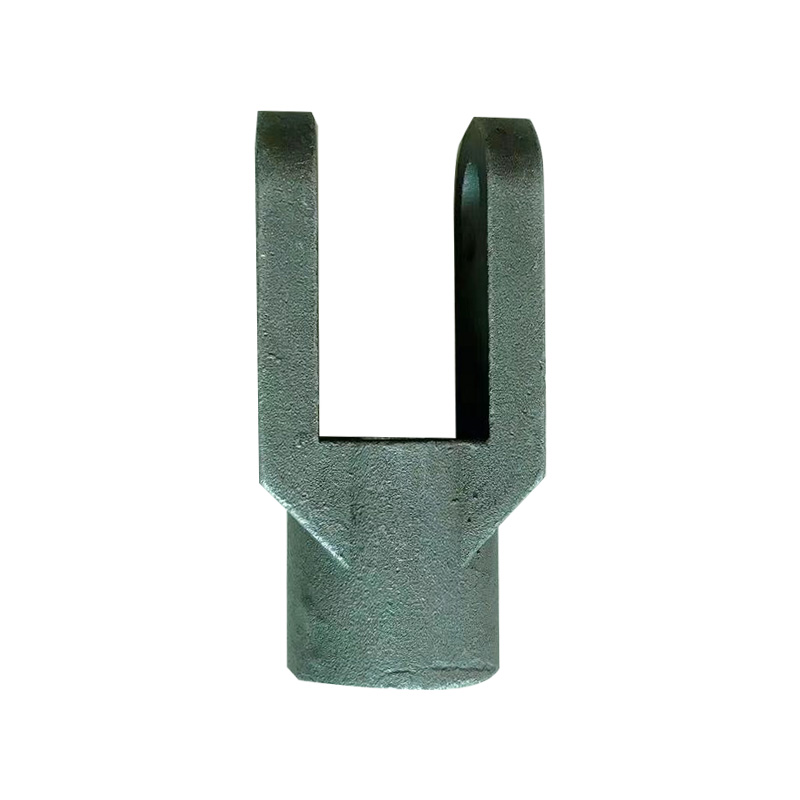

Cross-industry practices within automotive and bicycle manufacturing processes have greatly improved in many aspects thanks to the introduction of the Precision Die Cast Fork Lug. Its conception was aimed at surpassing the expectations of modern manufacturing.

precision die cast fork lugs are used as one of the components that provides suspension for bicycles or automobiles. DiMAX FFA Tower manufactured Precision Die Cast Fork Lugs is strong and durable thanks to its all-die-cast nature and allows for a great variance of shapes depending on design aspirations. This component is designed with such tight tolerances that it can be used in many applications that require it to suffice extreme conditions.

Superior Strength Fork Lug: Thanks to the combination of various alloys used to forge the fork lug, its tensile strength is unrivaled and guarantees a long service life even in extreme conditions.

Reduced Weight: The technology of advanced die-casting saves material under intense pressure while preserving the structure; thus, the simplest components will be both strong and lightweight.

Dimensional Accuracy: There is a noticeable more precise fit made by the tolerance then that made by the installer, this fits up parts with respect to time and adds to the efficiency of a complete system.

Resilience against corrosion is an important quality of the fork lug since it is coated with a finishing of good quality which is also suitable for use in difficult environment and enhances durability of the device.

Tailor made Solutions: The design is made flexible such that it can be designed to suit particular customers’ needs and hence constitue scalability across different applications in automotive and bicycle industries.

The precision die cast fork lug finds uses in:

Automotive Suspension Systems: These lugs assist in strengthening the vehicle’s stability and performance by serving as reliable connection points in the shock absorbers and suspension setups.

Bicycle Front Forks: For these lugs, their principal role is to allow smooth and safe rides using lightweight components that possess high strength for high-performance and recreational bicycles.

Specialized Machinery: These lugs are fitted in industrial machinery where high load capacity and precise components are required.

The Technology Advancement Conundrum

This product is a perfect example of how design and engineering needs to be refined through the eras of modernisation and eco-friendly techniques. This environmentally friendly solution is strengthened by die-casting technology which cuts down on excessive waste throughout the manufacturing process.

Definitely, the Precision Die Cast Fork Lug is more than a single component, within a competitive market is a combination of innovative technologies, superior quality and the ability to meet requirements. With the recent combination of factors that the device possesses, it is indeed at the center of the takeover on technologies of the future generation in the automotive and bicycle industries.

The Precision Die Cast Fork Lug makes sense as a sound investment in a more reliable future for manufacturers aiming to increase the product performance and reliability.