Forklift Casting Parts a crucial role in the functionality of forklifts. These parts are important components used in the construction and assembly of forklifts. They are typically made of high-quality materials such as iron, steel, or aluminum, designed to withstand extreme conditions and heavy loads. forklift casting parts of forklift castings is their durability and strength. These parts can withstand the wear and tear of daily use in industrial environments, making them an ideal choice for forklifts. In addition, even under extreme temperatures and pressures, cast parts can maintain their shape and structure, ensuring the safety and reliability of forklifts. forklift casting parts of forklift castings is their versatility. These parts can be customized and designed to meet specific requirements and specifications, making them suitable for various forklift applications. Whether lifting heavy objects in the warehouse or transporting goods in the distribution center, forklifts can efficiently and effectively cast parts.

Logistics and warehousing industry: Forklifts are widely used in the logistics and warehousing industry for loading, unloading, stacking, and short distance transportation operations.

Transportation industry: Forklifts are used for the handling and stacking of goods in transportation fields such as ports, stations, and airports.

Industrial manufacturing: Forklifts are used in factory workshops and manufacturing to improve production efficiency and material handling.

Wholesale and retail industry: Forklifts are used for warehouse management and rapid handling of goods in the circulation and retail of goods.

Distribution Center: Forklifts are used in distribution centers to improve the efficiency of goods sorting and distribution.

In the field of construction machinery, forklift casting components are also used in the field of construction machinery, such as balance weights used in forklifts, aerial work vehicles, loaders, as well as on the axle of reducers in trucks, construction machinery vehicles, and other vehicles.

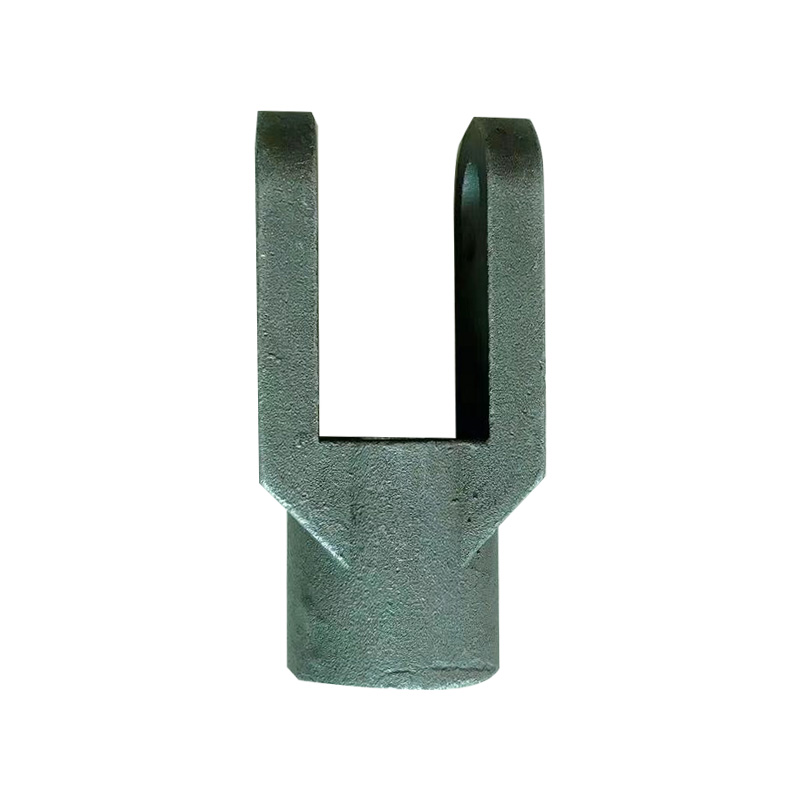

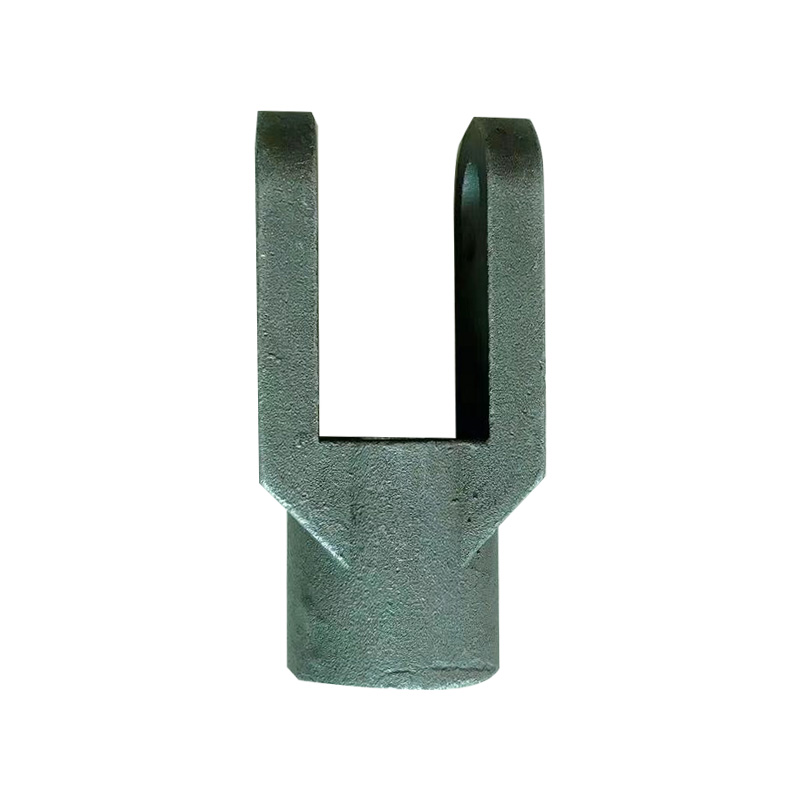

Precision Die Cast Fork Lug Features:

High strength and wear resistance: Forklift casting components, such as counterweights (counterweights), usually need to withstand significant forces and impacts, so material selection is crucial, requiring high strength, wear resistance, and strong impact resistance.

Material diversity: The materials used for forklift casting components can include ordinary steel, low-alloy steel, and special alloy steel such as Q235, Q345, 16Mn, 16MnDR, WH60E, etc. These materials have good toughness and strength.

Heat treatment and surface treatment: In order to improve the service life and safety performance of forklift casting components, some parts such as fork heads will undergo heat treatment or surface treatment to increase their hardness and durability.

Green and environmentally friendly: With the increasing demand for environmental protection, more and more green and environmentally friendly processes and technologies are being adopted in the production process of forklift casting parts.

Efficient production: The production of forklift casting components is accompanied by comprehensive upgrades in technology and equipment, and production capacity continues to rise to meet the pursuit of efficient operations.

| Name | Precision Die Cast Fork Lug |

| Material | ZG35 |

| Process | Coated Sand / Water Glass Investment Casting |

| Weight | 0.3 Kg |

| Product Standard | GB/T699-88 |

Frequently Asked Questions (FAQs):

What materials are used in the manufacturing of the Precision Die Cast Fork Lug?

This high quality material makes this fork lug through processes such as resin sand casting and water glass precision casting.

Can the Precision Die Cast Fork Lug be customized according to specific requirements?

Yes, we make our products according to customer’s drawing so that it can meet precisely what our clients have specified.

What industries commonly use this Precision Die Cast Fork Lug?

For instance, this particular fork lug always supports these industries where most of them prefer frame connection systems especially when dealing with their pallet truck applications as well as material handling equipment industries too.

How does the die-casting process benefit the product?

For example, die cast process makes sure that there is high precision, consistency, durability so that this becomes reliable and efficient for the main application.

Dongron is dedicated to providing high-quality machining and precision casting products. This is well shown through precision die-cast fork lug. To find out more information about our products and how we can assist you with your requirements, please contact us today.